It was in bad shape, so I needed to get all new metal. Automotive Specialties fit the bill with replacement stuff for the top edge of the window, the side pillar pieces (L&R), and the bottom rear deck filler piece.

After a long time of cleaning rust, using Osflo (metal prep) and POR-15 paint, I had the fun time of trying to fit the metal back that I had ripped out! After a few weeks of working around the Hot weather in the Spring, I had it pretty much completed. The Lincoln Weld-Pac 100 welder had worked great (0.025" wire and CO2/Argon gas). Next, I would take a break (unintentionally), since the summer here in NC was a scorcher!

Trunk Shelf & Side Pillar Repair

Before

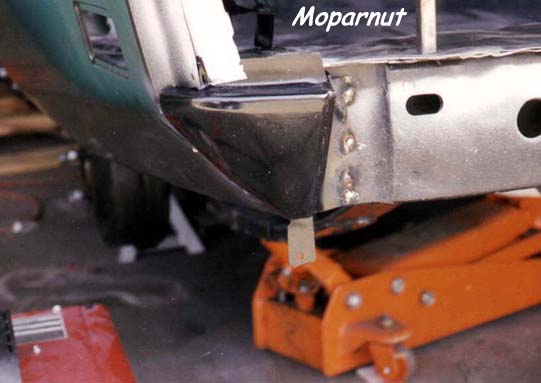

Metal has all been replaced! Whew... (POR-15 on the frame rails, etc.)

I also had a spot rotted out where the left side of the trunk lid met the trunk. After hand bending it, I had a piece as good as new...

After

Sept. Oct. - 1999

Well, after a long break over the summer-time (due to the super hot weather this year in NC), I had started to get back in the swing of fixing the rest of the trunk.

The hardest part that I could see was trying to get everything centered back in place. I had to align the rear valance panel, rear 1/4's, trunk floor, & trunk extensions!

After getting everything prepped, I put in the trunk floor pan. Next, the trunk extensions were put in place.

Trunk floor is drilled out, next it is plug welded to the frame.

Trunk floor and trunk extensions are welded in. Notice that I had rebuild the window regulators while the side of the car is missing, much easier to do it now than later on!

Rear 1/4's welded on!

Rear 1/4 end cap welded on - Left

Rear 1/4 end cap welded on - Right

Notice the damage repaired from a previous accident (from the previous owner)

Rear valance welded on

Next Page

Home

Trunk Shelf & Side Pillar Repair

Before

Metal has all been replaced! Whew... (POR-15 on the frame rails, etc.)

I also had a spot rotted out where the left side of the trunk lid met the trunk. After hand bending it, I had a piece as good as new...

After

Sept. Oct. - 1999

Well, after a long break over the summer-time (due to the super hot weather this year in NC), I had started to get back in the swing of fixing the rest of the trunk.

The hardest part that I could see was trying to get everything centered back in place. I had to align the rear valance panel, rear 1/4's, trunk floor, & trunk extensions!

After getting everything prepped, I put in the trunk floor pan. Next, the trunk extensions were put in place.

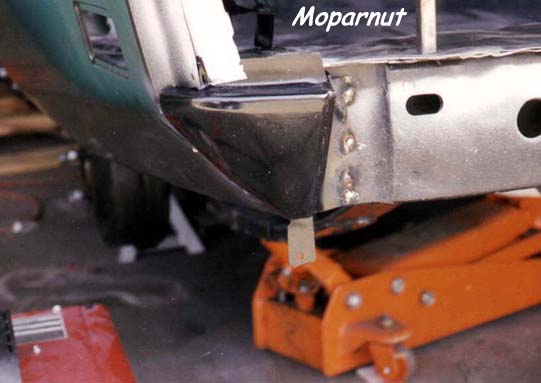

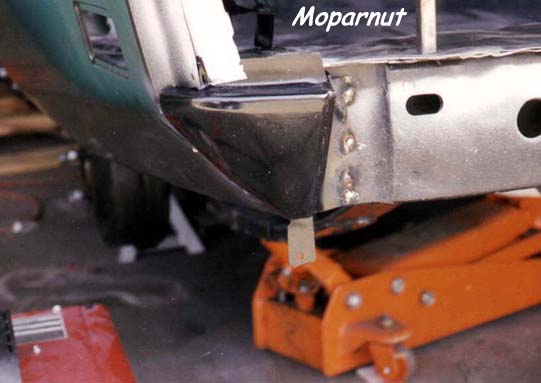

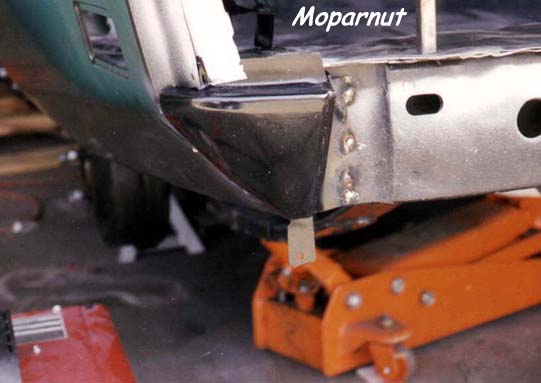

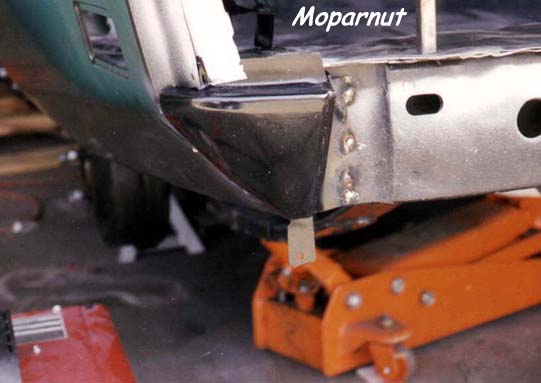

Trunk floor is drilled out, next it is plug welded to the frame.

Trunk floor and trunk extensions are welded in. Notice that I had rebuild the window regulators while the side of the car is missing, much easier to do it now than later on!

Rear 1/4's welded on!

Rear 1/4 end cap welded on - Left

Rear 1/4 end cap welded on - Right

Notice the damage repaired from a previous accident (from the previous owner)

Rear valance welded on

Next Page

Home

After getting everything prepped, I put in the trunk floor pan. Next, the trunk extensions were put in place.

Trunk floor is drilled out, next it is plug welded to the frame.

Trunk floor and trunk extensions are welded in. Notice that I had rebuild the window regulators while the side of the car is missing, much easier to do it now than later on!

Rear 1/4's welded on!

Rear 1/4 end cap welded on - Left

Rear 1/4 end cap welded on - Right

Notice the damage repaired from a previous accident (from the previous owner)

Rear valance welded on

Next Page

Home

Trunk floor is drilled out, next it is plug welded to the frame.

Trunk floor and trunk extensions are welded in. Notice that I had rebuild the window regulators while the side of the car is missing, much easier to do it now than later on!

Rear 1/4's welded on!

Rear 1/4 end cap welded on - Left

Rear 1/4 end cap welded on - Right

Notice the damage repaired from a previous accident (from the previous owner)

Rear valance welded on

Next Page

Home

Rear 1/4's welded on!

Rear 1/4 end cap welded on - Left

Rear 1/4 end cap welded on - Right

Notice the damage repaired from a previous accident (from the previous owner)